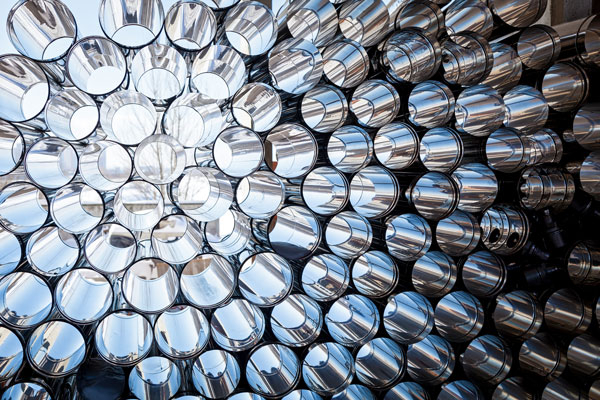

Corrosion Resistant alloys

A Corrosion-Resistant Alloy (CRA) is an alloy consisting of metals such as chrome, stainless steel, cobalt, nickel, iron, titanium, and molybdenum. When combined, such metals can promote corrosion resistance more than other components like carbon steel. This type of alloy offers reliable protection from corrosion, eradicating the need for expensive maintenance and repair. Wrought Material […]

Quality Assurance

All our Quality Assurance efforts are supported each and every day through a qualitative specification assurance process which is second to none. We maintain complete material traceability not only to the manufacturer but to the origin of the raw material as well. All material composition and property data is maintained in our in-house data storage […]

Heat Resistant alloys

Heat-resistant alloys have high creep resistance and strength at high temperatures. They are used as the construction material for parts of internal combustion engines, steam and gas turbines, jet engines, furnaces, and atomic-power installations. HIGH TEMPERATURE HEAT RESISTANT ALLOYS:

Alloy 625 & Its Uses

Inconel® Alloy 625 & its Uses Alloy 625 (made of nickel and chromium) is used because of its outstanding fabricability (including joining), high corrosion resistance, and high strength. Temperature for service ranges from supercooled to 982C. The toughening effect of niobium and molybdenum on the nickel-chromium structure gives Alloy 625 its strength property; consequently, precipitation […]

Alloy 020 & its Uses

Alloy 020 & its Uses Alloy 020 has dependable corrosion resistance in environments with sulfuric acid, and the ability to withstand corrosive environments, such as chlorides and nitric acid, is also useful. The main difference between Alloy 20 and Alloy 21 is their carbon content: while Alloy 20 is low in carbon, Alloy 21 is […]