High Nickel Alloy, Specialty Stainless Steel & Titanium Grade 2 & 7

Custom

Fabrication

Custom

Fabrication

Precision Fabrication Controlled Through PA Inc.

Inspections, Audits, NDE, & Supporting Specification Comfirmation Documentation

Here you will find a detailed list of our custom-manufactured products, ranging from transition pieces to high-pressure alloy castings, pipe, and fittings.

- Transition Pieces

- Alloy HP cast Tubes and Fittings

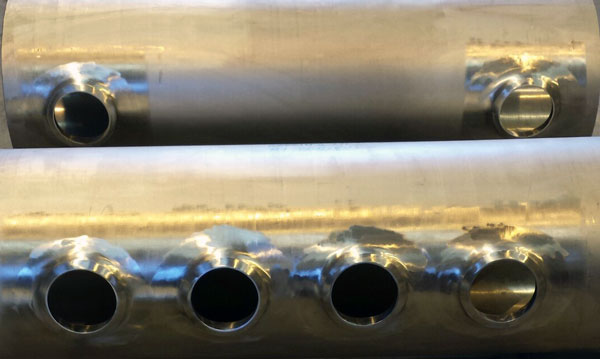

- Extruded Manifolds/Headers

- Cones

- Bullhorn Assemblies

- Crosses

- Pigtails

- Laterals

- Return Bends

- Elbows

- Tees

- Nozzles

“Customer satisfaction guaranteed.”

Overall, high nickel piping is sought after for its exceptional combination of corrosion resistance, strength, and versatility, making them vital components in critical industries and challenging environments.

- High nickel piping offers exceptional resistance to corrosion, making them ideal for applications in corrosive environments such as chemical processing plants and marine structures.

- The elevated strength and durability of high nickel pipes ensure reliable performance in high-pressure and high-temperature applications, guaranteeing long-lasting and efficient operation.

- With customizable options available, high nickel piping can be tailored to suit specific project requirements, providing a perfect fit and ensuring optimal performance for various industries and applications.

P.A. Inc Delivers Quality To The

Highest Standards

Superior Corrosion & Heat Resistance:

Our high nickel alloy piping is crafted with premium materials, ensuring exceptional resistance to corrosion and heat. With our piping, you can rely on long-lasting performance even in harsh environments, providing a cost-effective solution for your projects.

Enhanced Strength and Durability:

High nickel content in our piping offers remarkable strength and durability, making them ideal for applications that require critical service. Whether for industrial processes, marine projects, or lethal infrastructure, our high nickel alloy piping ensures reliable and efficient performance under demanding conditions.

Customized Solutions:

We pride ourselves on providing tailored solutions to meet your specific requirements. Our team of experts will work closely with you to understand your project needs and deliver high nickel piping with precise dimensions, finishes, and configurations, ensuring a perfect fit for your applications. Experience the difference of personalized service and top-quality products for your projects.

High Temperature

Heat Resistant alloy

Corrosion Resistant

Corrosion resistant alloy

Quality Assurance

In-House Certified Technicians

Seven Uses For High Nickel Pipe & Fittings

- Chemical Processing: High nickel piping is widely used in chemical processing plants, where they can handle corrosive and aggressive chemicals at high temperatures. Their excellent resistance to corrosion and oxidation makes them ideal for such environments.

- Petrochemical Industry: In the petrochemical industry, high nickel piping is utilized for transporting and processing hydrocarbons and other fluids. Their ability to withstand extreme temperatures and harsh conditions makes them essential for this sector.

- Power Generation: High nickel piping has applications in power plants, particularly in areas where high-temperature and high-pressure conditions are present, such as in boilers, heat exchangers, and steam lines.

- Marine and Offshore Structures: Due to their resistance to saltwater corrosion, high nickel piping is commonly used in marine and offshore structures, including pipelines, platforms, and vessels.

- Aerospace and Defense: In aerospace and defense applications, high nickel piping is employed for their ability to handle high stress, extreme temperatures, and aggressive environments.

- Pharmaceutical and Food Processing: High nickel piping is suitable for pharmaceutical and food processing industries, where strict hygiene standards are required, thanks to their corrosion resistance and easy cleanability.

- Desalination Plants: High nickel piping is used in desalination plants to handle the high salinity and corrosive nature of seawater during the desalination process.